8.2 France carries out technical audits on all the components of your power plant

The profitability of a power plant is based how each component of which it is composed is functionning, and requires specific knowledge. The team of experts from 8.2 France performs all the necessary technical inspections and measures on all the power plant components. Moreover, thanks to the experience developed by the group and acquired on the main European photovoltaic installations, both onshore and offshore projects, we can provide our customers with precious support with extensive skills and a pragmatic approach.

Foundation expertise / Site supervision

Foundation expertise

Poorly thought out, poorly constructed or poorly maintained, foundations can be the “feet of clay” of wind turbines.

Once backfilled and hidden under the surface, the foundation must support without flaws and for several decades, hundreds of tonnes, themselves subject to the constraints of the wind.

Through its experience, 8.2 France is able to bring its expertise to all stages of the foundation’s life.

in the pre-construction phase

- Geotechnical studies analysis

- Development of specifications

- Technical advice on methods, materials and service providers

In the construction phase

- Reinforcement / formwork control and flow monitoring

post-construction & operation phase

- Cracks analysis / waterproofness / MALT control

- Measurement of vertical movement of rotation and oscillation

Site supervision

In addition, Our teams monitor wind and photovoltaic sites and verify that the key steps have been completed.

- Monthly visits and inspections with reports

- Civil engineering phase assistance (especially for foundations)

- HSE monitoring

- Planning follow-up

- Verification of assembly & Technical audits of acceptance of works

- Performance analysis (Run test & Performance Ratio)

Technical Audits

Our experts come from the maintenance departments of the main manufacturers. Their experience, enriched by their missions at 8.2 France, gives them in-depth knowledge of the technology and ensures their mastery of their specificities.

These technical audits can be carried out at different times in the life of the installations:

Reception audit

At the time of commissioning, during which our experts can assist you to carry out blade inspections on the ground before assembly, and an audit called mechanical acceptance to reduce the list of reserves before the end of the site.

End of warranty audit

Audit of end of maintenance contract

8.2 France teams support you to audit the general condition of your installation. During this inspection, more than 200 points are checked in order to:

- Check that the electricity production facility allows the various parties to work safely

- Perform visual examinations of the condition of the installation and the components

- Check compliance with the installation with regard to regulations

inspections from the ground

Blades are major component that can impact the remaining life of a wind turbine. Therefore, they must withstand enormous stresse, are subjected to extreme load fluctuations and directly exposed to environmental influences, such as temperature changes, precipitation, UV rays or lightning, and their manufacture meets very high size requirements and of form.

In order to support our customers on their blade inspections and comply with their HSE policy, we have developed blade inspection techniques from the ground.

These techniques require high performance equipment which can reveal structural defects which are difficult to see (cracks), but which are indicative of the mechanical weaknesses of the blade, and which must be detected as soon as possible.

Our technologies:

Standard photoscope – 900 mm focal length

HD Photoscope – 2000 mm focal length

Infrared thermoscope

On rope inspections

Due to their difficult access, blades are not checked with reasonable frequency or in appropriate ways. Their high velocity and location expose them to numerous environmental constraints (wind, hail, lightning strike) and may cause defects such as :

- Cracks

- Lightning impacts

- Erosion

- …

These defects can have knock-on effects on production, noise emission and/or blade stability and safety. In order to guarantee high quality inspection, 8.2 France recommends a precise contact inspection on ropes or with a cherry picker Each visible defect is identified while going down along the blade in order to inspect each part of the structure:

- Leading edge

- Trailing edge

- Suction side

- Pressure side

Moreover, this inspection is performed with tapping in order to identify delamination and a continuity measurement of the earthing cable. These inspections can be followed by regular inspections with a special camera from the ground with binoculars. The outdoor condition of the tower is also checked by rope access. Simultaneously the items below are checked:

- Paint condition

- Corroded areas particularly near the flanges.

- Gap thickness at the flange

- Paint thickness using an ultrasonic device

Our experts are all IRATA certified and then skilled to perform these examinations safely.

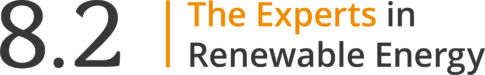

Vibration analyses

Occasional monitoring of vibrations is strongly recommended before the end of the contracts to anticipate component failure and negotiate with the maintenance provider in the event of doubt or early warning.

Ideally, a first vibratory signature is requested during commissioning, otherwise it will be used as is. We recommend carrying out a vibration campaign on all the machines.

Procedure:

Preparation inside the turbine:

- Stop the turbine

- Turn the key to local mode to avoid interference with a third party

- Press the pause button

- The technician accompanying our auditor mounts the turbine

- For the turbine without lifting, the winch is activated to lift the equipment

- The vibration monitoring expert goes up to join the technician

Our expert has compiled a database of most of the characteristics of the transmission components (in particular the gearbox, which is the most complex component to assess).

These will be required from the manufacturer to make the best measurements. Most of the time, the number of teeth in the gearbox and other key indications can be obtained from the analysis itself.

The report will include all the turbines in the same wind farm, and will provide the operator with the main results. Detailed information can be obtained on request (spectra and measurements from the data logger).

Video-endoscopy

Since 2004, the 8.2 group has used video-endoscopy and has carried out more than 3000 checks. Video endoscopy is a visual examination that uses a video camera. There is no other technology that allows such rapid examination of difficult to access areas such as cavities or the internal components of a machine.

Objective :

In wind turbines, video endoscopy is first used to examine multipliers.

Our statistics show that 5 to 10% of the multipliers inspected by video-endoscopy at the end of the warranty must be replaced. In general, it will take a change in multiplier over the life of a machine (in operation over 20 years) for a normally windy fleet.

For multipliers with 1 planetary stage this operation is carried out in 3 to 4 hours and makes it possible to reveal any premature wear of the different stages in the multiplier including the bearings accessible outside the oil.

We can also improve our diagnosis by taking gearbox oil samples.

our references

THE KEY FIGURES FOR 8.2 FRANCE IN ONSHORE WIND

1000

video-endoscopies carried out since 2012

1 200

vibration measurements carried out since 2012

900

blade angle discrepancies readjusted since 2013

250

foundations appraised since 2014

THEY TRUST US